Overview of monitoring engine and generator sets

Generator remote monitoring is an important part of a modern facilities management program and is becoming increasingly affordable for organizations of all sizes. Many options are available to monitor emergency backup or primary power generators. The main topics covered in this article are:

• Overview of monitoring engine and generator sets

• Key parts of remote monitoring systems

• Remote monitoring considerations

Many options are available to allow faciliti

es managers, owners, and maintenance providers to monitor and interface with standby or primary power generator sets. Monitoring engine parameters allows maintenance teams to become aware of developing problems and perform early diagnosis. Repairing issues before they advance to shut down failures increases the reliability of diesel and natural gas generators. Basic configurations of remote monitoring solutions include:

•

OEM specific monitoring solutions – Many OEMs offer proprietary remote monitoring systems with their new generators or as upgrades to older model generators. The monitoring software links directly to the advanced control panel. These solutions include:

- Caterpillar Cat Connect

- Cummin’s Power Command

- MTU Go! Manage

- Kohler PowerScan

- Generac Power Zone Pro Sync

- Mesa Natural Gas Telemetry and Operations Data Center (ODC) app

•

Aftermarket remote monitoring systems – specialty equipment manufacturers offer upgrade kits that allow monitoring hardware to be added to an existing generator. Systems vary in terms of additional systems to install and breadth of data fields to be monitored. Top after market solutions include:

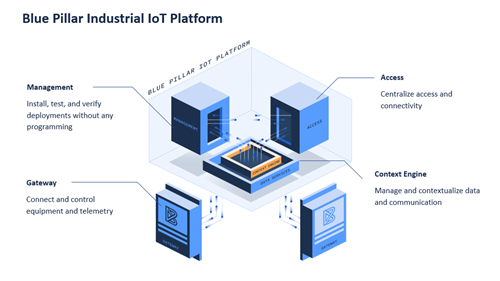

- Blue Pillar OnsitePower

- Omnimetrix

- Monico

- GenTracker

Key parts of remote monitoring systems

Monitoring system connection to the generator

Remote monitoring systems gather data from the generator’s engine and generator end before transmitting it to a remote gateway. There are three common practices for gathering this information:

•

ECM with advanced control panel generator sets – all new generators (since the late 1990’s) utilize digital control panels that interface directly with the ECM to control generator operation. Remote monitoring systems gather generator information through a MODBUS/MODLON connection to the control panel.

•

ECM (engine control module) controlled generator sets - Newer generator sets incorporate a generator control module (monitors generator parameters) and engine control module (monitors engine parameters) into single operating system. This configuration allows for advanced parameter monitoring through a remote monitoring gateway. The remote monitoring system generally connects to the generator through the MODBUS/MODLON connection.

•

Non-ECM controlled generator sets - Older generator sets (1990’s and prior) did not utilize modern ECMs to control operations and instead relied on analog controls & gauges. Monitoring capabilities for this type of genset is limited to analog signals converted to digital signal via an A to D converter. Basic generator set parameters can be monitored but can require specialty-wiring harnesses.

Data transmission to gateway

Once the remote monitoring system has gathered data from the generator, it must transmit it back to a processing software / database to be made useful to outside users. The communication can be accomplished through a variety of methods:

•

Cellular IOT (internet of things) connection – Since most generators are installed in areas with strong cellular service, many remote monitoring solutions leverage industrial 4G connections through providers like AT&T and Verizon. This provides a relatively cheap solution to connecting generators without significant additional wiring.

•

Satellite IOT connection – Remote monitoring systems for mobile generators need to communicate with their gateway from a variety of locations. Generators designed for use in austere environments, such as Mesa Natural Gas Solutions, feature an Iridium satellite link (with concurrent cellular connection) to reliably communicate with the base station.

•

Hardwired connection – In applications without sufficient cell coverage or where extreme data security is required, a hard wired connection (e.g., RJ45 ethernet) can be used to connect the generator’s data to a processing application.

•

Remote annunciator panel – Mission critical facilities governed by NFPA 110 (e.g., hospital generators) may require a hardware solution that includes remote notification / alerts of generator status and error codes. These devices are generally used to provide notice of the generator’s status to a 24/7 monitored facility or control room.

User remote access to generator

Once the generator’s data has been transmitted to a remote software, users can interact with this information in a variety of ways. Onsite or cloud applications process generator data and make it accessible to authorized users. These uses may include:

•

Alerts – Alerts on a generator automatically starting or a significant error status are the most common push notifications through remote monitoring software. These notifications can some in the form of SMS text messages, email alerts, or automated phone calls. Alerts are an essential part of remote monitoring because they can let the facilities team know of a grid outage or an issue with a backup generator.

•

Fleet status monitoring – Organizations with multiple generators can benefit from a map view of their equipment fleet and the high-level status of each unit. This allows maintenance managers to actively track their equipment status and coordinate repair activities as issues arise.

•

Real time generator statistics – The best monitoring solutions, such as Blue Pillar’s OnsitePower, provide a near real time (<5 sec delay) view into the generators vital operating parameters. This can be extremely useful to generator technicians trying to diagnose an issue remotely or for monitoring the operation of a generator that is running.

•

Remote start / stop – Remote monitoring systems allow users to remotely start or stop a generator. This feature can provide facilities teams with an extra method of controlling the generator when not physically on site.

•

Data history – Technicians and maintenance teams can use catalogued operational history to understand and diagnose generator faults prior to dispatching repair teams. The history viewer can help personnel identify when an issue first arose and look for operating stats during scheduled generator exercises.

Monitoring system considerations

Some considerations should be made when selecting the generator monitoring system for an application. Below are some items to consider:

•

System capability – Will the selected system meet all monitoring and communication needs, and allow for future growth?

•

System security – How will the monitoring system integrate with site-specific security concerns as well as with existing IT infrastructure (if system runs through corporate system)?

•

Fleet compatibility – Will the monitoring system integrate with other generators in the fleet and any supervisory control and data acquisition (SCADA) systems in use?

•

Points to monitor on generator set – Will the system allow the user to monitor the all of the needed data fields (e.g., engine temperature, battery voltage)?

•

Selection of fuel tank level monitor - several choices are generally available for monitoring fuel levels. The 4 to 20 ma or 0-5/0-10 V DC level monitors are widely used and considered more accurate.

>>Back to Articles & Info<<